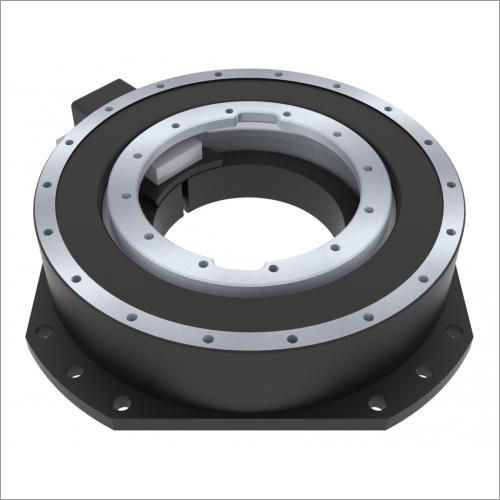

Rotary Table Bearing

Price 8899 INR/ Piece

Rotary Table Bearing Specification

- Cage Material

- Brass / Polyamide / Steel

- Lubrication Type

- Grease / Oil Lubrication

- Thickness

- 36 mm

- Inside Diameter

- 100 mm

- Precision Rating

- P4 / P5

- Retainer

- Integrated

- Bearing Type

- Rotary Table Bearing

- Material

- Chrome steel (GCr15)

- Structure

- Four-point contact ball bearing

- Seals Type

- Open / Shielded

- Number Of Rows

- Single Row

- Bore Size

- 100 mm

- Outside Diameter

- 180 mm

- Limiting Speed

- 900 rpm

- Load Capacity

- High radial and axial load capacity

- Surface Finish

- Ground and polished

- Mounting Type

- Flange mount

- Operating Temperature Range

- -20°C to +80°C

- Hardness

- HRC 60-62

- Vibration Resistance

- High

- Dynamic Load Rating

- 295 kN

- Application

- Rotary tables, indexing heads, machine tools, automation equipment

- Static Load Rating

- 415 kN

- Corrosion Resistance

- Yes, with anti-corrosive treatment

Rotary Table Bearing Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About Rotary Table Bearing

Rotary Table Bearing is typically used to support rotating tables, indexing tables and milling heads. Its internal design, together with its high degree of running accuracy, enables very precise positioning of the workpiece or the working head. Rotary Table Bearing goes through varied quality checks prior to the final dispatch from our unit.

Product Details

Mounting Hole Type | Through Hole |

Type of Bearing | Slewing |

Usage/Application | Automotive Industry |

Shape | Round |

Seals Type | Single Seal |

Bore Diameter | 11 inch |

Material | Stainless Steel |

Exceptional Load Capacity and Precision

Designed with single-row, four-point contact technology, this rotary table bearing supports substantial radial and axial loads while maintaining high rotational accuracy. Precision ratings of P4 and P5 guarantee optimal performance in mission-critical automation and machining operations.

Engineered for Performance and Durability

Constructed from chrome steel (GCr15) and finished with a polished surface, this bearing resists corrosion and harsh environments. Its high hardness (HRC 60-62) and anti-corrosive treatment enhance lifespan, making it ideal for continuous or heavy-duty use.

Versatile Mounting and Sealing Options

Available in both open and shielded seal types, the bearing accommodates various operational environments. Its flange mount design simplifies installation on rotary tables, indexing heads, and precision equipment, ensuring a secure fit and reliable rotation.

FAQs of Rotary Table Bearing:

Q: How is the Rotary Table Bearing typically installed?

A: The rotary table bearing is designed for flange mounting, making it straightforward to attach securely to rotary tables, indexing heads, or machine tools. Ensure the mounting surface is clean and flat, and follow the recommended torque for fastener tightening to maintain alignment and performance.Q: What applications is this bearing best suited for?

A: This bearing is ideal for rotary tables, indexing heads, automation equipment, and high-precision machine tools. Its combination of high load capacity, robustness, and precision ensures reliable rotation in demanding industrial environments.Q: When should I choose the open or shielded seal type?

A: Select an open seal for applications where routine maintenance and lubrication are accessible, and where minimal contamination is expected. Opt for the shielded version in environments where protection from dust and debris is required, enhancing bearing longevity.Q: Where can I purchase this rotary table bearing in India?

A: As a distributor, exporter, manufacturer, and supplier based in India, we supply these rotary table bearings across India and internationally. Contact us directly or visit our official website to place orders or request technical support.Q: What benefits does the anti-corrosive treatment provide?

A: The anti-corrosive treatment significantly increases the bearings resistance to oxidation and rust, making it suitable for humid or chemically exposed environments. This ensures longer service intervals and reliable operation, even under challenging conditions.Q: How should I lubricate this bearing for optimal performance?

A: This bearing supports both grease and oil lubrication. For general applications, high-quality grease is recommended for consistent lubrication and protection. For high-speed operations (up to 900 rpm), oil may offer superior thermal stability. Always use lubricants compatible with chrome steel and follow the recommended lubrication intervals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Unit Bearings Category

Rex Bearing

Price 2674 INR / Piece

Minimum Order Quantity : 1000 Pieces

Limiting Speed : 10000 RPM m/s

Bore Size : 25 mm

Structure : Deep Groove

Number Of Rows : Single Row

DDR Bearing

Price 1495 INR / Piece

Minimum Order Quantity : 1000 Pieces

Limiting Speed : 35000 RPM

Bore Size : 6 mm

Structure : Double Direction Radial

Number Of Rows : Other, Single

FD FAN Bearing

Price 1499 INR / Piece

Minimum Order Quantity : 1000 Pieces

Limiting Speed : 3600 rpm sq m/hr

Bore Size : 8 mm

Structure : Deep Groove

Number Of Rows : Other, Single

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese