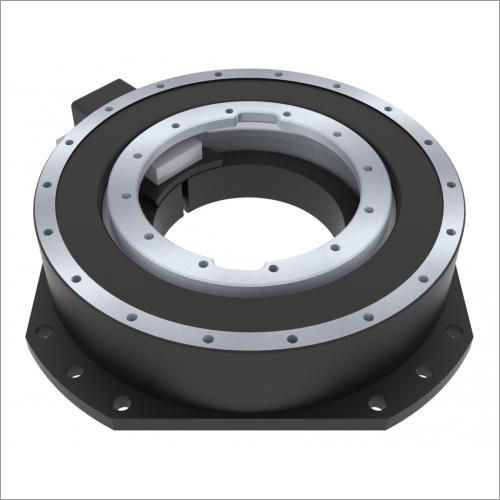

DDR Bearing

Price 1495 INR/ Piece

DDR Bearing Specification

- Lubrication Type

- Grease

- Inside Diameter

- 6 mm

- Thickness

- 5 mm

- Cage Material

- Steel

- Retainer

- Steel

- Precision Rating

- P6

- Bearing Type

- Ball Bearing

- Material

- Chrome steel

- Structure

- Double Direction Radial

- Seals Type

- Open

- Number Of Rows

- Single

- Bore Size

- 6 mm

- Outside Diameter

- 16 mm

- Limiting Speed

- 35000 RPM

- Load Capacity

- Standard

- Finishing

- Polished

- Feature

- Corrosion resistant

- Tolerance

- Standard

- Shape

- Round

- Dynamic Load Rating

- 2.73 kN

- Application

- Used for motors, machinery, and equipment

- Static Load Rating

- 1.27 kN

- Temperature Range

- -20°C to +120°C

- Noise Level

- Low

DDR Bearing Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About DDR Bearing

DDR Bearing is a dual layered roller type friction reducing element that is commonly used in various industrial machines, automotives, and other units to ensure smooth and efficient operation without the risk of excessive wearing. The material used is provided with chrome coating that gives an excellent protection from rust that ultimately leads to longer service life. It is available in various sizes with a diameter in between 10 to 90 millimeters. The offered DDR Bearing availed by us can be delivered to our customers as per the order placed by them at a low price range.

Product Details ofDDR Bearing

|

Max. Bore Size |

90 mm |

|

Type of Bearing |

Needle |

|

Surface Finishing |

Polished |

|

Number Of Rows |

Double Row |

|

Material |

Stainless Steel |

|

Usage |

Industrial |

|

Min. Bore Size |

10 mm |

Exceptional Performance and Durability

Designed for motors and heavy-duty machinery, DDR Ball Bearings offer robust performance in applications where stability and longevity are paramount. Manufactured using premium chrome steel and advanced polishing techniques, these bearings resist corrosion and function seamlessly across a wide temperature spectrum from -20C to +120C. Their open design facilitates effective grease lubrication and contributes to a longer operational life.

Optimized for Industrial Applications

With low noise emissions and a load capacity suited for standard industrial requirements, DDR Ball Bearings are engineered for single-row, double-direction radial motion. The precise P6 rating supports operations up to 35,000 RPM, making these bearings particularly suitable for high-speed equipment. Their versatility is further enhanced by compatibility with standard cages and retainers made from steel.

FAQs of DDR Bearing:

Q: How should DDR Ball Bearings be installed for optimal performance?

A: Proper installation involves ensuring the bearing is fitted into its housing using appropriate tools, avoiding direct strikes on the bearing rings. Accurate alignment, use of recommended grease, and checking shaft and housing dimensions according to standard tolerances ensure reliable, low-noise, and high-speed performance.Q: What are the primary applications of DDR Ball Bearings?

A: DDR Ball Bearings are used extensively in motors, machinery, and various types of equipment where reliable rotational motion is required. Their corrosion resistance, low noise, and ability to operate at speeds up to 35,000 RPM make them ideal for both industrial and commercial uses.Q: When is it necessary to replace DDR Ball Bearings?

A: Replacement is typically needed if you notice increased noise, vibration, or a decrease in operational efficiency. Routine maintenance and inspection as per equipment schedules help identify early signs of wear or grease depletion, ensuring timely replacement to avoid equipment downtime.Q: Where can DDR Ball Bearings be sourced from?

A: As a distributor, exporter, manufacturer, and supplier based in India, DDR Ball Bearings can be ordered directly from our official outlets or through authorized industrial supply partners. Contacting us ensures access to genuine products and technical support.Q: What is the process for maintaining DDR Ball Bearings?

A: Regular cleaning and re-lubrication with suitable grease, as well as periodic checks for wear or damage, are vital. For open bearings, ensure contaminant-free environments and use appropriate lubricants to extend service life and retain low noise characteristics.Q: What are the benefits of using DDR Ball Bearings in equipment?

A: DDR Ball Bearings offer excellent corrosion resistance, withstand high operational speeds, and provide stable performance under standard load conditions. Their polished finish, precision manufacturing, and robust materials contribute to longer equipment life and reduced maintenance needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Unit Bearings Category

FD FAN Bearing

Price 1499 INR / Piece

Minimum Order Quantity : 1000 Pieces

Precision Rating : P6

Material : Stainless Steel

Outside Diameter : 22 mm Perch

Thickness : 7 mm Square Feet

Rotary Table Bearing

Price 8899 INR / Piece

Minimum Order Quantity : 1000 Pieces

Precision Rating : P4 / P5

Material : Other, Chrome steel (GCr15)

Outside Diameter : 180 mm

Thickness : 36 mm

Rex Bearing

Price 2674 INR / Piece

Minimum Order Quantity : 1000 Pieces

Precision Rating : P6

Material : Chrome steel

Outside Diameter : 62 mm Foot (ft)

Thickness : 17 mm Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese