Rex Bearing

Price 2674 INR/ Piece

Rex Bearing Specification

- Lubrication Type

- Grease Lubrication

- Inside Diameter

- 25 mm

- Retainer

- Steel

- Cage Material

- Steel

- Precision Rating

- P6

- Thickness

- 17 mm

- Bearing Type

- Ball Bearing

- Material

- Chrome steel

- Structure

- Deep Groove

- Seals Type

- Double Shielded

- Number Of Rows

- Single Row

- Bore Size

- 25 mm

- Outside Diameter

- 62 mm

- Limiting Speed

- 10000 RPM

- Load Capacity

- High

Rex Bearing Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About Rex Bearing

Rex Bearing is the one which whose seal keeps contaminates out and lubricants in. The right seal means a longer life for your bearing, and with a wide variety of seal options, this bearing can be customized for high-speed, high-temperature, wet or high-contaminate environments. Rex Bearing can be availed from us at feasible rates.

Product Details

Max. Bore Size | 50 mm |

Type of Bearing | Pillow Block |

No. Of Row | Single Row |

Brand | Rex |

Material | SS |

Application | Machinery |

Min. Bore Size | 12 mm |

Engineered for Industrial Reliability

Rex Bearings robust structure, featuring high-quality chrome steel and a double-shielded design, makes it suitable for heavy-duty industrial machinery. Its polished deep groove and steel retainer ensure consistent, efficient performance, even in harsh operating environments.

Corrosion Resistance for Extended Service Life

Designed for environments prone to moisture or adverse conditions, Rex Bearing offers excellent corrosion resistance, helping to reduce maintenance and replacement costs. Its polished chrome steel build supports uninterrupted usage over extended periods.

Precision Performance with High Load Capacity

With a dynamic load rating of 28 kN and static load rating of 16 kN, Rex Bearing is tailored for machinery requiring high load capacity. The P6 precision rating and low vibration ensure smooth, reliable operation at speeds up to 10,000 RPM.

FAQs of Rex Bearing:

Q: How is Rex Bearing used in industrial machinery?

A: Rex Bearing is designed to support rotating shafts and reduce friction in industrial machines, ensuring reliable motion control and stability. Its high load capacity and precision rating make it ideal for applications such as motors, gearboxes, and conveyors.Q: What are the benefits of the bearings double-shielded seals?

A: Double-shielded seals help prevent dust, debris, and moisture from entering the bearing, enhancing durability and reducing the need for frequent maintenance, which extends the bearings service life.Q: When should Rex Bearing be considered for an industrial application?

A: Rex Bearing is ideal when your machinery requires high load handling, low vibration, and reliable performance in moderate to high-speed conditions, especially where corrosion resistance and operational stability are important.Q: Where can Rex Bearing be distributed or supplied?

A: Rex Bearing is available for distribution, export, and supply throughout India, catering to diverse industries with demanding machinery needs.Q: What is the process for installing Rex Bearing?

A: The bearing should be installed using standard press-fit methods, ensuring the shaft and housing are clean and within tolerance. It is recommended to use appropriate tools to avoid bearing damage during installation.Q: How does the bearings high-speed capability benefit machinery?

A: With a limiting speed of 10,000 RPM, Rex Bearing accommodates machinery that operates at high rotational speeds without loss of efficiency or increased wear, making it suitable for equipment requiring rapid and continuous operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Unit Bearings Category

DDR Bearing

Price 1495 INR / Piece

Minimum Order Quantity : 1000 Pieces

Lubrication Type : Grease

Material : Chrome steel

Inside Diameter : 6 mm

Retainer : Steel

FD FAN Bearing

Price 1499 INR / Piece

Minimum Order Quantity : 1000 Pieces

Lubrication Type : Grease

Material : Stainless Steel

Inside Diameter : 8 mm

Retainer : Pressed Steel

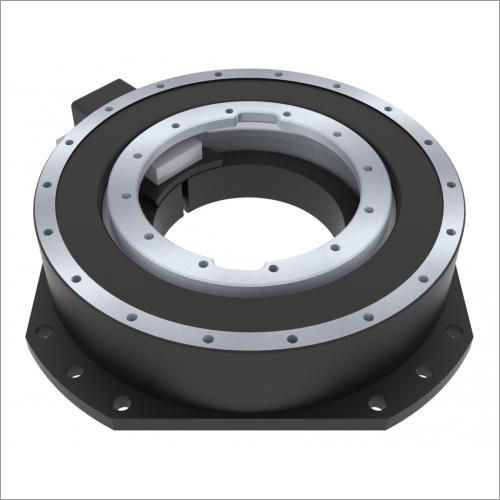

Rotary Table Bearing

Price 8899 INR / Piece

Minimum Order Quantity : 1000 Pieces

Lubrication Type : Other, Grease / Oil Lubrication

Material : Other, Chrome steel (GCr15)

Inside Diameter : 100 mm

Retainer : Integrated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese