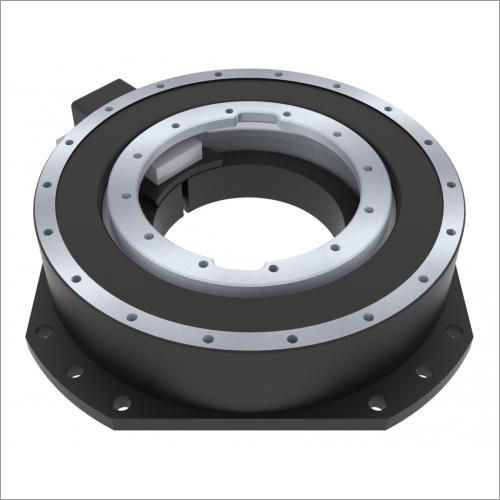

FD FAN Bearing

Price 1499 INR/ Piece

FD FAN Bearing Specification

- Retainer

- Pressed Steel

- Precision Rating

- P6

- Thickness

- 7 mm Square Feet

- Inside Diameter

- 8 mm Centimeter (cm)

- Lubrication Type

- Grease

- Cage Material

- Steel

- Bearing Type

- Ball Bearing

- Material

- Stainless Steel

- Structure

- Deep Groove

- Seals Type

- Shielded

- Number Of Rows

- Single

- Bore Size

- 8 mm

- Outside Diameter

- 22 mm Perch

- Limiting Speed

- 3600 rpm sq m/hr

- Load Capacity

- High Kilograms (kg)

- Temperature Range

- -20C to 120C

- Noise Level

- Low Noise

- Finish Type

- Polished

- Application

- Used in FD (Forced Draft) Fans and Electric Motors

- Static Load Rating

- 1560 N

- Dynamic Load Rating

- 3650 N

FD FAN Bearing Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About FD FAN Bearing

We are one of the leading manufacturers of FD FAN Bearing in the market. It is used for forced draft, induced draft and process air in steam power generation. It can range from a few hundred to several thousand horsepower. Speeds are moderate in FD FAN Bearing and usually between 300 and 900 RPM.

Product Details

|

Inner Diameter |

26 mm |

|

Type of Bearing |

Ball Bearing |

|

Outside Diameter |

160 mm |

|

Material |

SS |

|

Weight |

0.045 kg |

|

Thickness |

8 mm |

|

Number of Row |

Single Row |

|

Limiting Speed |

19000 r/min |

Reliable Bearings for Demanding Applications

Our FD FAN Bearings are specially designed to provide reliable and efficient performance in FD (Forced Draft) Fans and electric motor applications. With a durable stainless steel construction and a precision P6 rating, these ball bearings are built for environments where high load capacities and minimal noise are critical. Their polished finish and shielded structure ensure extended service life, even in challenging conditions.

Quality Construction and Easy Compatibility

Featuring a deep groove, single row construction and premium steel cage, these bearings offer high dynamic and static load ratings. With bore and outside diameters of 8 mm and 22 mm respectively, they are compatible with standard fan and motor designs. Grease lubrication and shielded seals make them exceptionally low-maintenance. Their versatility and reliability make them ideal for industrial, commercial, and export applications.

FAQs of FD FAN Bearing:

Q: How should the FD FAN Bearing be installed in FD fans or electric motors?

A: To install the FD FAN Bearing, ensure the bore and outside diameters (8 mm and 22 mm, respectively) match your machinerys specifications. The deep groove, single row design makes it suitable for direct press fitting onto shafts commonly found in FD fans and electric motors. Always mount bearings using appropriate tools to prevent damage.Q: What are the main advantages of using this bearing in FD fans or electric motors?

A: This bearing offers high load capacity, low noise operation, and reliable performance across a broad temperature range (-20C to 120C). The shielded, grease-lubricated design minimizes maintenance needs, while the polished stainless steel finish enhances durability and corrosion resistance.Q: When should the FD FAN Bearing be replaced?

A: Replace the bearing if you detect abnormal noise, excessive vibration, increased operating temperature, or visible wear. Routine inspections during scheduled maintenance will help catch signs of wear early, ensuring consistent machinery performance.Q: Where is this FD FAN Bearing manufactured and exported from?

A: Our FD FAN Bearings are manufactured, exported, and supplied from India. As a trusted distributor, exporter, manufacturer, and supplier, we cater to domestic and international markets with quality-assured products.Q: What is the lubrication process for this bearing, and does it need re-lubrication?

A: This bearing comes pre-lubricated with high-grade grease and features shielded seals for long-lasting lubrication. Under standard operating conditions, re-lubrication is typically unnecessary, making this bearing ideal for low-maintenance applications.Q: How does the bearings structure and materials improve its performance?

A: The deep groove, single row structure, coupled with stainless steel and a steel cage, enhances load-carrying capacity and precision (P6 rating), increases resistance to wear and corrosion, and supports speeds up to 3600 rpm, ensuring efficient, reliable operation even under demanding conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Unit Bearings Category

DDR Bearing

Price 1495 INR / Piece

Minimum Order Quantity : 1000 Pieces

Inside Diameter : 6 mm

Outside Diameter : 16 mm

Structure : Double Direction Radial

Seals Type : Open

Rotary Table Bearing

Price 8899 INR / Piece

Minimum Order Quantity : 1000 Pieces

Inside Diameter : 100 mm

Outside Diameter : 180 mm

Structure : Fourpoint contact ball bearing

Seals Type : Open / Shielded

Rex Bearing

Price 2674 INR / Piece

Minimum Order Quantity : 1000 Pieces

Inside Diameter : 25 mm Perch

Outside Diameter : 62 mm Foot (ft)

Structure : Deep Groove

Seals Type : Double Shielded

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese