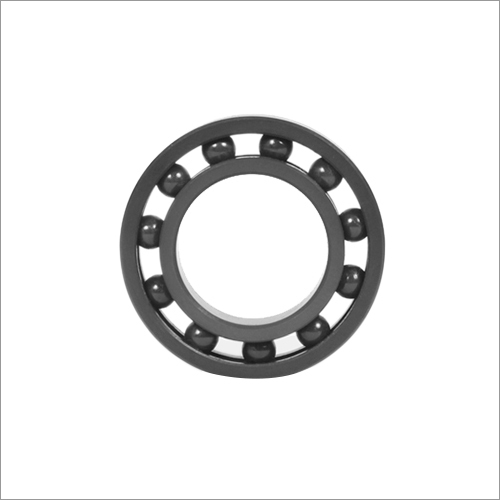

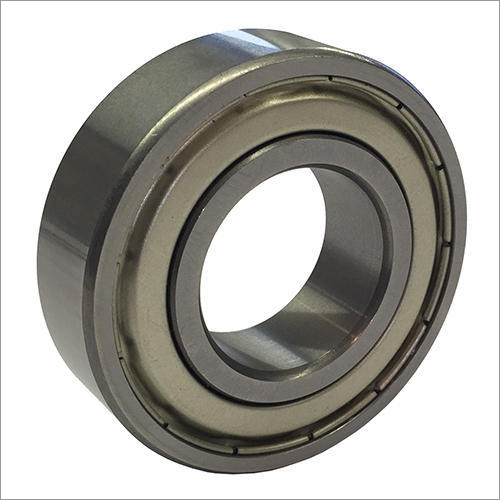

Miniature Ball Bearing

Price 899 INR/ Piece

Miniature Ball Bearing Specification

- Cage Material

- Steel

- Inside Diameter

- 6 mm

- Retainer

- Steel

- Precision Rating

- ABEC-3

- Lubrication Type

- Grease

- Thickness

- 6 mm

- Bearing Type

- Miniature Ball Bearing

- Material

- Chrome steel

- Structure

- Deep Groove

- Seals Type

- Open / Shielded

- Number Of Rows

- Single Row

- Bore Size

- 6 mm

- Outside Diameter

- 19 mm

- Limiting Speed

- 36000 RPM

- Load Capacity

- High Radial Load

- Noise Level

- Low

- Temperature Range

- -20°C to 120°C

- Application

- Ideal for small mechanical equipment, robotics, and medical instruments

- Packaging Type

- Box

- Corrosion Resistance

- Yes

- Finish

- Polished

Miniature Ball Bearing Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About Miniature Ball Bearing

We have been serving our clients with a quality tested range of Miniature Ball Bearing in the market. It is used for extremely high speeds. It offers a low level of noise, vibration, and frictional torque performance. Miniature Ball Bearing can be sealed by shields or rubber seals to prevent leakage of lubricating grease or entry of dust.

Product Details

No of Row | Single Row |

Usage/Application | Automotive Industry |

Bore Size | 80 mm |

Outside Diameter | 200 mm |

Lubrication | Light Oil |

Material | Stainless Steel |

Thickness | 30 mm |

Superior Quality & Performance

Precision-engineered from robust chrome steel, this miniature ball bearing delivers impressive durability and performance. The deep groove design and ABEC-3 rating provide optimal load bearing with minimal noise, making these bearings perfect for high-speed and accurate use.

Versatile Application Range

These bearings are ideally suited for small-scale mechanical assemblies, robotics, and sensitive medical devices. Their compact structure, high corrosion resistance, and ability to withstand extreme temperatures make them indispensable for advanced engineering projects.

Custom Packaging & Supply

Delivered in sturdy box packaging, these bearings maintain integrity during transport and storage. Available for wholesale distribution across India, we cater to distributors, exporters, manufacturers, and suppliers seeking reliable, high-quality miniature bearings.

FAQs of Miniature Ball Bearing:

Q: How should Miniature Ball Bearings be installed in small mechanical equipment or robotics?

A: These bearings should be pressed into correctly sized housings, ensuring alignment and preventing unnecessary force on the inner or outer race. This precise installation helps preserve bearing life, especially in delicate mechanical or robotic setups.Q: What key advantages does a deep groove and single row structure provide?

A: The deep groove and single row structure offer higher radial load capacity and improved rotational speed, making them particularly effective in applications requiring smooth, stable, and low-noise operation.Q: When should you choose an open versus a shielded seal type?

A: Choose an open seal if the bearing operates in a clean, easily accessible environment for frequent lubrication. Opt for shielded bearings in dusty or harsh conditions, as the shield helps resist contamination and retain lubricant.Q: Where can these bearings be utilized outside of robotics and medical instruments?

A: Beyond robotics and medical equipment, these miniature ball bearings are suitable for use in precision tools, model machinery, small motors, and instrumentation where compact size and reliable performance are crucial.Q: What is the recommended process for lubricating these bearings?

A: Grease lubrication is advised; apply a suitable quality grease compatible with chrome steel bearings. Periodic re-lubrication may be required depending on the operational environment and speed to maintain optimal performance.Q: How does corrosion resistance benefit the longevity of these miniature ball bearings?

A: Corrosion resistance ensures the bearings maintain their performance and structural integrity even in humid or chemically exposed environments, significantly extending service life and reducing maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SS Bearings Category

6207 Linear Ball Bearing

Price 109 INR / Piece

Minimum Order Quantity : 1000 Pieces

Bore Size : 35 mm

Number Of Rows : Other, Single

Material : Other, High Carbon Chromium Steel

Bearing Type : Other, Linear Ball Bearing

Double Row Deep Groove Ball Bearings

Price 1949.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Bore Size : 25 mm

Number Of Rows : Other, 2

Material : Other, Chrome Steel (GCr15)

Bearing Type : Ball Bearing

Crankshaft Bearing

Price 1699 INR / Piece

Minimum Order Quantity : 1000 Pieces

Bore Size : 38 mm

Number Of Rows : Other, 1

Material : Other, Steel

Bearing Type : Other, Crankshaft Bearing

Hybrid Bearing

Price 5579.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Bore Size : 6 mm

Number Of Rows : Other, Single

Material : Other, Ceramic Balls, Stainless Steel Rings

Bearing Type : Other, Hybrid

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese