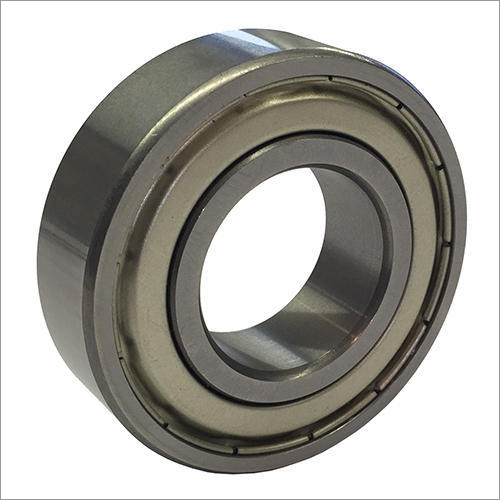

Double Row Deep Groove Ball Bearings

Price 1949.00 INR/ Piece

Double Row Deep Groove Ball Bearings Specification

- Lubrication Type

- Grease / Oil

- Thickness

- 15 mm

- Retainer

- Pressed Steel

- Precision Rating

- ABEC 3 / P6

- Inside Diameter

- 25 mm

- Cage Material

- Steel / Nylon

- Bearing Type

- Ball Bearing

- Material

- Chrome Steel (GCr15)

- Structure

- Double Row Deep Groove

- Seals Type

- Open / Sealed Options Available

- Number Of Rows

- 2

- Bore Size

- 25 mm

- Outside Diameter

- 52 mm

- Limiting Speed

- Up to 10000 RPM (varies with lubrication and size)

- Load Capacity

- High Radial and Axial Load

- Shape

- Round

- Dimension Stability

- High

- Corrosion Resistance

- Yes

- Noise Level

- Low

- Surface Finish

- Polished

- Vibration Level

- Minimal

- Temperature Range

- -40°C to 120°C

- Static Load Rating

- 8.1 kN

- Dynamic Load Rating

- 12.8 kN

- Application

- Automobile, Electric Motors, Transmission, Industrial Machinery

Double Row Deep Groove Ball Bearings Trade Information

- Minimum Order Quantity

- 200 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About Double Row Deep Groove Ball Bearings

We are an acclaimed manufacturer of Double Row Deep Groove Ball Bearings in the market. These are suitable for medium radial loads and small axial loads in both directions. The design and function of these Double Row Deep Groove Ball Bearings are similar to a pair of single-row ball bearings. These are used in applications where the load capacity of the single-row bearing is insufficient.

Product Details

|

Bore Size |

60 mm |

|

Type of Bearing |

Ball Bearing |

|

Outside Diameter |

190 mm |

|

Shape |

Round |

|

Material |

Stainless Steel |

|

Thickness |

30 mm |

|

Structure |

Deep Groove |

Superior Performance Across Industries

Double Row Deep Groove Ball Bearings are preferred in automobiles, electric motors, and heavy machinery for their ability to sustain high radial and axial loads. Their chrome steel material and polished finish enhance durability, resist corrosion, and maintain reliable performance even in extreme temperatures or continuous operation scenarios.

Versatile Design and Easy Installation

Featuring open and sealed variants and a standard round shape, these bearings are suitable for a wide range of applications. With ABEC 3/P6 precision and pressed steel or nylon cage options, they offer flexibility and accurate fit. Installation and maintenance are straightforward, catering to manufacturers, suppliers, and end-users alike.

FAQs of Double Row Deep Groove Ball Bearings:

Q: How do Double Row Deep Groove Ball Bearings differ from single row bearings?

A: Double row deep groove ball bearings provide increased load capacity and greater stiffness compared to single row variants. Their dual rows of balls help accommodate higher radial and axial loads, making them ideal for applications requiring robust support and reliable dimension stability.Q: What are the main applications for these ball bearings?

A: These bearings are commonly used in automobiles, electric motors, transmissions, and industrial machinery due to their high load handling capacity, polished surface for reduced friction, and corrosion resistance, ensuring reliable operation in diverse environments.Q: When should I choose sealed versus open type bearings?

A: Sealed bearings are preferable in environments exposed to dust, moisture, or contaminants, as they help retain lubricant and block debris. Open type bearings may be selected for cleaner conditions or when manual re-lubrication is feasible and necessary for specific operational requirements.Q: Where can these bearings be installed within automotive or industrial equipment?

A: These bearings fit in any rotating assembly requiring high-speed, stable performancesuch as wheel hubs, alternators, electric motor shafts, and transmission systems. Their standardized dimensions (25 mm bore, 52 mm outside diameter, 15 mm thickness) allow compatibility with a range of machinery and vehicle components.Q: What is the recommended lubrication process for these bearings?

A: Either grease or oil lubrication can be used, depending on the application and speed requirements. For most general uses, high-quality grease is sufficient and helps extend operational life. In high-speed environments, oil may offer better cooling and reduced internal friction.Q: What benefits do these bearings provide to manufacturers and end-users?

A: Manufacturers and end-users benefit from these bearings high load ratings, low noise and vibration, and robust corrosion resistance. Their dimensionally stable design ensures consistent performance across a wide temperature range and reduces downtime due to maintenance or premature wear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SS Bearings Category

Hybrid Bearing

Price 5579.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Number Of Rows : Other, Single

Material : Other, Ceramic Balls, Stainless Steel Rings

Bearing Type : Other, Hybrid

Bore Size : 6 mm

Motorcycle Bearings

Price 1559.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Number Of Rows : Single Row

Material : Chrome steel

Bearing Type : Other, Motorcycle Wheel Bearing

Bore Size : 17 mm

Crankshaft Bearing

Price 1699 INR / Piece

Minimum Order Quantity : 1000 Pieces

Number Of Rows : Other, 1

Material : Other, Steel

Bearing Type : Other, Crankshaft Bearing

Bore Size : 38 mm

Gearbox Bearing

Price 599.00 INR / Piece

Minimum Order Quantity : 300 Pieces

Number Of Rows : Single Row

Material : Chrome steel

Bearing Type : Ball Bearing

Bore Size : 35 mm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese