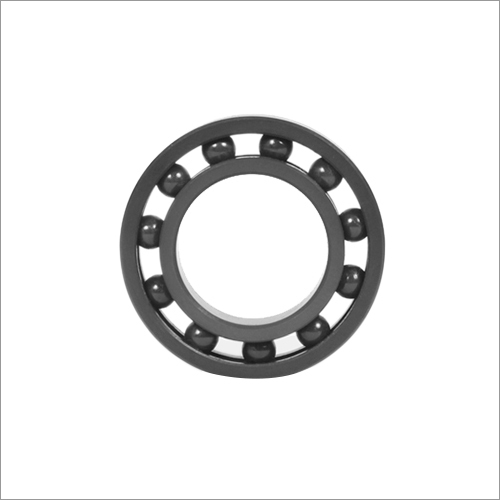

Crankshaft Bearing

Price 1699 INR/ Piece

Crankshaft Bearing Specification

- Thickness

- 9 mm

- Retainer

- Yes

- Cage Material

- Steel

- Inside Diameter

- 38 mm

- Lubrication Type

- Grease

- Precision Rating

- P6

- Bearing Type

- Crankshaft Bearing

- Material

- Steel

- Structure

- Single Row

- Seals Type

- Open

- Number Of Rows

- 1

- Bore Size

- 38 mm

- Outside Diameter

- 62 mm

- Limiting Speed

- 7000 RPM

- Load Capacity

- High

- Hardness

- HRC 58-64

- Corrosion Resistance

- Yes

- ISO Certification

- ISO 9001:2015

- Application

- Automotive engines, Marine engines, Industrial engines

- Surface Finish

- Precision Ground

- Shape

- Round

- Minimum Order Quantity

- 100 Pieces

- Temperature Range

- -30°C to +150°C

Crankshaft Bearing Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About Crankshaft Bearing

Crankshaft Bearing is the one used in internal combustion engines to provide its rotation under inertia forces generated by the parts of the shaft and oscillating forces transmitted by the connecting rods. Main bearings are mounted in the crankcase. Crankshaft Bearing goes through varied quality checks before the final dispatch from our unit.

Product Details

|

Structure |

Deep Groove |

|

Bore Size |

75 mm |

|

Outside Diameter |

185 mm |

|

Shape |

Round |

|

Brand |

BBH |

|

Material |

SS |

|

Thickness |

30 mm |

Exceptional Durability and Precision

Our crankshaft bearing is crafted with precision-ground finish and hardened steel, delivering outstanding durability and precision under intense loads. Its single-row structure ensures optimal rotation, even at speeds up to 7000 RPM. Suited for a wide temperature range, the bearing remains highly reliable across automotive, marine, and industrial applications.

Certified Quality and Corrosion Resistance

Adhering to ISO 9001:2015 certification, our crankshaft bearings guarantee a high standard of quality and consistency. The corrosion-resistant steel ensures longevity in challenging environments, making them ideal for demanding engine assemblies. The open seal design also facilitates efficient grease lubrication and easy maintenance.

FAQs of Crankshaft Bearing:

Q: How do I select the appropriate crankshaft bearing for my engine application?

A: To select the right crankshaft bearing, ensure the bore size (38 mm), outside diameter (62 mm), and thickness (9 mm) match your engines specifications. Also consider the bearings load capacity, working temperature range (-30C to +150C), and required speed (up to 7000 RPM). Consult your engine manual or our support team for detailed compatibility.Q: What are the main benefits of using this crankshaft bearing in automotive, marine, or industrial engines?

A: This bearing provides high load capacity, excellent durability due to HRC 58-64 hardness, and reliable operation at high speeds. Its corrosion-resistant and ISO 9001:2015 certified steel construction ensures a longer lifespan and reduced maintenance, making it dependable for various engines.Q: When should I replace the crankshaft bearing in my engine?

A: Replacement is recommended if you detect noise, excessive vibration, or visible wear during routine maintenance. Its also advisable to replace the bearing if your engine is undergoing a major overhaul, or has operated under severe conditions for extended periods.Q: Where can I purchase or order these crankshaft bearings?

A: These bearings are available for distribution, export, and supply throughout India. Orders can be placed directly with the manufacturer or through authorized distributors and suppliers. Minimum order quantity is 100 pieces.Q: What process ensures the quality and performance of this crankshaft bearing?

A: The bearing undergoes precision grinding, rigorous quality checks, and is manufactured to meet ISO 9001:2015 standards. Every bearing is made from high-quality steel and tested for hardness, precision rating (P6), and corrosion resistance before being approved for shipment.Q: How is the crankshaft bearing lubricated, and what type of maintenance does it require?

A: This bearing is designed for grease lubrication. Ensure regular lubrication intervals according to your engines maintenance schedule, and inspect for signs of wear or contamination to maintain optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in SS Bearings Category

Gearbox Bearing

Price 599.00 INR / Piece

Minimum Order Quantity : 300 Pieces

Precision Rating : P6

Lubrication Type : Grease

Material : Chrome steel

Limiting Speed : 12000 RPM

Hybrid Bearing

Price 5579.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Precision Rating : P6

Lubrication Type : Grease

Material : Other, Ceramic Balls, Stainless Steel Rings

Limiting Speed : 75000 rpm

Motorcycle Bearings

Price 1559.00 INR / Piece

Minimum Order Quantity : 200 Pieces

Precision Rating : P6

Lubrication Type : Grease

Material : Chrome steel

Limiting Speed : 13000 RPM m/s

Miniature Ball Bearing

Price 899 INR / Piece

Minimum Order Quantity : 1000 Pieces

Precision Rating : ABEC3

Lubrication Type : Grease

Material : Chrome steel

Limiting Speed : 36000 RPM

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese