Swing Bearing

Price 1394 INR/ Piece

Swing Bearing Specification

- Thickness

- 110 mm Gauge

- Retainer

- Integral

- Precision Rating

- P5

- Lubrication Type

- Other

- Cage Material

- Steel

- Inside Diameter

- 750 mm Millimeter (mm)

- Bearing Type

- Swing Bearing

- Material

- Other

- Structure

- Four-point contact ball bearing

- Seals Type

- Double rubber seal

- Number Of Rows

- Single Row

- Bore Size

- Customized as per model

- Outside Diameter

- 900 mm Perch

- Limiting Speed

- 30 rpm RPM

- Load Capacity

- High, up to 2500 kN Metric Ton

- Temperature Range

- -25°C to +80°C

- Packaging Type

- Wooden Box or Export Quality Packaging

- Surface Treatment

- Phosphated, Painted, or Customized Finish

- Application

- Excavators, Cranes, Wind Turbines, Rotating Machinery

- Rotation Type

- Internal Gear, External Gear, or Non-Gear options

- Mounting Holes

- Equally Spaced Through Holes and Threaded Holes (per design)

- Noise Level

- Low Noise Operation

- Coating

- Anti-Rust Oil Applied

Swing Bearing Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About Swing Bearing

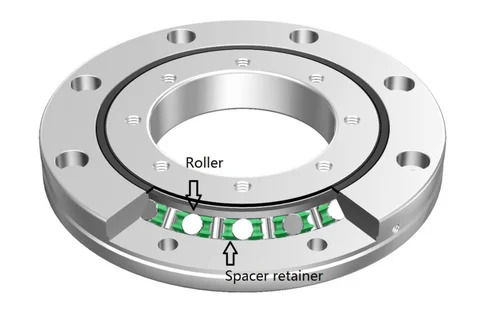

Swing Bearing

We are a prestigious manufacturer of Swing Bearing in the market. It comprises an inner ring and an outer ring, one of which usually incorporates a gear. Together with attachment holes in both rings, Swing Bearing enables an optimized power transmission with a simple and quick connection between adjacent machine components.

Product Details

|

Finish |

Chrome Plated |

|

Usage/Application |

Automotive Industry |

|

Bore Size |

80 mm |

|

Outside Diameter |

200 mm |

|

Material |

Stainless Steel |

|

Thickness |

30 mm |

|

Structure |

Cylindrical roller |

High-Performance and Customizability

This swing bearing offers robust performance and is customizable to meet specific needs. With various gear configurations, bore sizes, and surface treatments offered, it adapts to both standard and unique industrial applications. Its high-load design ensures consistent performance in critical machinery like cranes and wind turbines.

Reliable Operation in Extreme Conditions

Designed to deliver stability even in harsh conditions, the swing bearing endures wide temperature fluctuations, resists corrosion, and maintains lubrication through double rubber seals and grease lubrication. Its P5 precision rating ensures efficient, low-noise operation throughout its long service life.

Secure Packaging and Professional Supply Chain

Each bearing is packed in sturdy wooden boxes or export-grade packaging, maintaining integrity during transit. As a distributor, exporter, manufacturer, and supplier from India, prompt and secure global delivery is assured for all clients.

FAQs of Swing Bearing:

Q: How is the swing bearing installed given the mounting hole options?

A: Swing bearings can be mounted using equally spaced through holes or threaded holes, as specified in the design. This facilitates flexible and secure attachment to various machinery frameworks, ensuring stable integration into cranes, excavators, and other heavy-duty equipment.Q: What applications benefit most from using this swing bearing?

A: This swing bearing is especially advantageous for use in rotating machinery, wind turbines, cranes, and excavators. Its high load capacity and customizable features make it suitable for any application requiring substantial axial, radial, and moment load resistance with smooth rotation.Q: When should I consider a customized surface finish?

A: A customized surface finish is recommended for environments with specific corrosion risks or aesthetic requirements. For example, marine or offshore settings may call for enhanced anti-rust protection beyond standard phosphating or painting.Q: Where is this swing bearing manufactured and supplied from?

A: The bearing is manufactured, exported, and supplied from India, ensuring rigorous quality standards and timely international delivery through established supply networks.Q: What is the process for selecting the optimal swing bearing configuration?

A: Selection involves specifying bore size, gear type (internal, external, or non-gear), mounting hole specification, material preferences, and surface finish requirements. Discussing the applications load and environmental demands with the supplier ensures an ideal match.Q: How does the double rubber seal design benefit usage?

A: Double rubber seals provide superior protection against dust, moisture, and contaminants, retaining lubricant and extending bearing lifespan, especially in outdoor and challenging industrial conditions.Q: What are the key benefits of choosing this swing bearing model?

A: Key benefits include high load capacity (up to 2500 kN), low noise operation, customized sizing, durable surface treatments, secure packaging, and flexible installation, making it a reliable choice for heavy-duty, precision-driven industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Bearings Category

Rolling Mill Bearing

Price 171 INR / Piece

Minimum Order Quantity : 100 Pieces

Thickness : Standard

Outside Diameter : 6 mm 200 mm

Bore Size : Custom as per requirement

Structure : Round

Swing Bearing BBH

Price 1394 INR / Piece

Minimum Order Quantity : 100 Pieces

Thickness : 30 mm

Outside Diameter : 200 mm

Bore Size : 80 mm

Structure : Cylindrical roller

Taper Bearings

Price 666 INR / Piece

Minimum Order Quantity : 1000 Pieces

Thickness : 17 mm Feet (ft)

Outside Diameter : 62 mm Foot (ft)

Bore Size : 30 mm

Structure : Tapered

UCP Series Bearings

Price 458 INR / Piece

Minimum Order Quantity : 100 Pieces

Thickness : 30 mm

Outside Diameter : 200 mm

Bore Size : 80 mm

Structure : Pillow Block

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese