Metal Cage Bearing

Price 5297 INR/ Piece

Metal Cage Bearing Specification

- Thickness

- 15 mm

- Cage Material

- Metal

- Retainer

- Pressed Metal

- Precision Rating

- P6

- Inside Diameter

- 25 mm

- Lubrication Type

- Grease / Oil

- Bearing Type

- Deep Groove Ball Bearing

- Material

- Chrome steel

- Structure

- Single row ball bearing

- Seals Type

- Open / Unsealed

- Number Of Rows

- Single

- Bore Size

- 25 mm

- Outside Diameter

- 52 mm

- Limiting Speed

- 12000 rpm

- Load Capacity

- 3500 N

- Surface Treatment

- Polished

- Application

- Automotive, Electrical Motors, Gearboxes, Machine Tools

- Operating Temperature Range

- -40°C to +120°C

Metal Cage Bearing Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 1 Week

About Metal Cage Bearing

We are a noteworthy manufacturer of Metal Cage Bearing in the market. Solid cages are used for smaller series and for reasons of strength used in large, high loaded bearings. Solid cages made out of light metal or phenolic have relatively small force of gravity and are often used in high-speed bearings as outer lip guided version. Metal Cage Bearing can be availed from us at economical prices.

Product Details

Max. Outside Diameter | 190 mm |

Shape | Round |

Number Of Row | Single Row |

Surface Finishing | Chrome Plated |

Seals Type | Open |

Material | Bearing Steel |

Min. Outside Diameter | 120 mm |

Precision Engineering for Versatile Applications

This bearing is fabricated with P6 precision, typifying its high manufacturing standards. Its structure supports single-row ball arrangement, which ensures smooth motion and minimal friction. Suitable for automotive, electrical motors, gearboxes, and machine tools, this bearing combines reliability with efficiency wherever rotational movement is required.

Performance Across Temperature Extremes

With an operational range from -40C to +120C, the bearing is ideal for environments with wide temperature variations. Its chrome steel material and polished finish enhance resistance to wear, while supporting a limiting speed of up to 12,000 rpmtailored for high-speed industrial operations.

FAQs of Metal Cage Bearing:

Q: How do I install this single row deep groove ball bearing in my machinery?

A: Begin by cleaning the shaft and housing, ensuring they are free from dust or debris. Align the bearing with the shaft, gently pressing it into place using an appropriate tool to avoid damaging the polished surface or metal cage. Always follow manufacturer-recommended procedures for best performance.Q: What advantages does a metal cage provide over other cage materials in this bearing?

A: The pressed metal cage offers superior strength, durability, and thermal stability compared to plastic alternatives. It effectively retains the ball bearings under high-speed and high-load conditions, making it ideal for automotive and industrial machinery applications.Q: When should I choose an open/unsealed bearing design like this one?

A: Open or unsealed bearings are suited for environments where regular maintenance and lubrication (using grease or oil) are possible. This design minimizes friction and allows for better heat dissipation, which is particularly beneficial in electric motors, gearboxes, and machine tools.Q: Where can these bearings be used effectively?

A: Their robust and versatile design makes them ideal for deployment in the automotive industry, electrical motors, gearboxes, and various machine tools. The bearings size and load capacity accommodate many medium-duty applications where reliable, low-maintenance rotation is required.Q: What is the lubrication process for this bearing?

A: Lubricate the bearing using either grease or oil before installation and periodically thereafter, as open bearings require regular lubrication. The frequency depends on the applications operating conditions and environment. Proper lubrication ensures smooth operation and extends the bearings service life.Q: What benefits does the P6 precision rating offer?

A: P6 precision rating indicates tighter manufacturing tolerances, which translates to improved bearing accuracy, quieter operation, and greater efficiency at high speeds. This is particularly advantageous in applications like machine tools and electric motors, where precision is crucial.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Bearings Category

SS Steering Bearings

Price 80 INR / Piece

Minimum Order Quantity : 100 Pieces

Structure : Standard Bearing

Outside Diameter : 200 mm

Number Of Rows : Single Row

Material : Stainless Steel

Textile Machinery Bearing

Price 150 INR / Piece

Minimum Order Quantity : 10 Pieces

Structure : Standard

Outside Diameter : Varies by model

Number Of Rows : Other, Single / Double

Material : Chrome steel

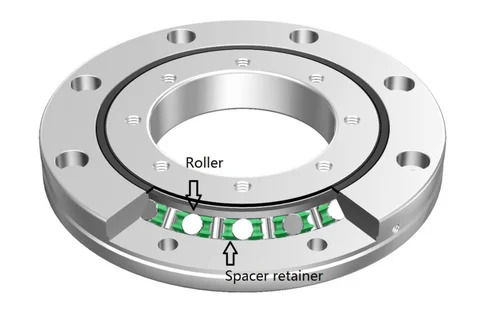

Swing Bearing BBH

Price 1394 INR / Piece

Minimum Order Quantity : 100 Pieces

Structure : Cylindrical roller

Outside Diameter : 200 mm

Number Of Rows : Single Row

Material : Other, Alloy Steel

Taper Bearings BBH

Price 366 INR / Piece

Minimum Order Quantity : 100 Pieces

Structure : Tapered

Outside Diameter : 200 mm

Number Of Rows : Single Row

Material : Chrome steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese