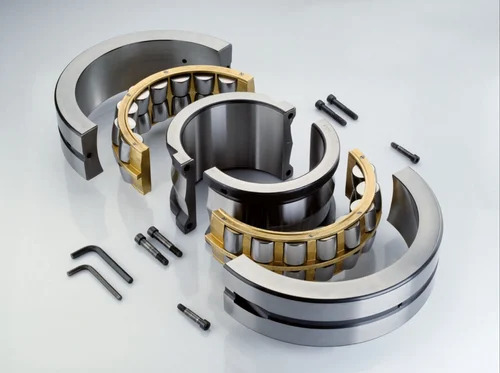

Brass Cage Bearing

Price 4627 INR/ Piece

Brass Cage Bearing Specification

- Inside Diameter

- 20 mm

- Precision Rating

- P6

- Lubrication Type

- Grease/Oil

- Retainer

- Machined Brass Cage

- Cage Material

- Brass

- Thickness

- 14 mm

- Bearing Type

- Ball Bearing

- Material

- Chrome steel

- Structure

- Deep Groove

- Seals Type

- Open

- Number Of Rows

- Single Row

- Bore Size

- 20 mm

- Outside Diameter

- 47 mm

- Limiting Speed

- 16000 RPM

- Load Capacity

- 7300 N

- Standard

- ISO 492

- Finish

- Polished

- Noise Level

- Low

- Application

- Automotive, Electrical Motors, Industrial Machinery

- Temperature Range

- -30°C to 120°C

- Shape

- Round

Brass Cage Bearing Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

About Brass Cage Bearing

We are a trusted name among the manufacturers of Brass Cage Bearing in the market. It offers high rigidity, high strength and can be used at high temperatures. This Brass Cage Bearing also offers the key features of absorbing lubricant and performing well in aggressive environments where lubrication is marginal.

Product Details

Max. Outer Diameter | 115 mm |

Usage/Application | Industrial |

Surface Finishing | Chrome Plated |

Number Of Row | Single |

Brand | BBH |

Material | Brass |

Structure | Cylindrical |

Min. Outer Diameter | 60 mm |

Highly Durable Chrome Steel Construction

Built from premium chrome steel with a polished finish, these brass cage ball bearings ensure exceptional durability and corrosion resistance. Their robust material construction is tailored to withstand heavy loads and challenging operational environments, offering prolonged service life for both high-speed and heavy-duty applications.

Precision and Compliance to International Standards

Manufactured to ISO 492 specifications and rated at P6 precision, these bearings guarantee consistent dimensional accuracy. This makes them especially suitable for use in scenarios demanding balanced performance, reliability, and low noise, such as advanced automotive systems and precision electric motors.

FAQs of Brass Cage Bearing:

Q: How should Brass Cage Bearings be lubricated for optimal performance?

A: Brass Cage Bearings are compatible with both grease and oil lubrication. For continuous, high-speed operation, regular lubrication is recommended to ensure smooth rotation, minimize wear, and maintain low noise levels. Always use lubricants suitable for chrome steel and the operating temperature range of -30C to 120C.Q: What are the primary benefits of using a brass cage in these ball bearings?

A: A machined brass cage provides excellent rigidity, reduced friction, and enhanced durability compared to alternatives. Brass resists wear and deformation under high-speed and high-load conditions, ensuring the bearing maintains performance while operating quietly and efficiently.Q: Where can these bearings be applied most effectively?

A: These bearings are ideally used in the automotive sector, electric motors, and various types of industrial machinery, thanks to their high load capacity, limiting speed of 16,000 RPM, and resistance to wide temperature fluctuations.Q: When should these bearings be replaced in machinery?

A: Bearings should be inspected regularly and replaced when signs of excessive noise, vibration, or increased play are detected. Replacement intervals depend on the intensity of operation, rotation speed, load, and environmental conditions within the application.Q: What is the process of selecting the correct bearing size?

A: Selecting the correct bearing involves considering the shaft diameter (20 mm), the external diameter (47 mm), and the required load capacity (7,300 N). Its also important to match the bearing type (single row, deep groove) and precision rating (P6) with your applications specifications.Q: How does the open seals type affect bearing maintenance and performance?

A: With an open seals design, these bearings are easier to lubricate and visually inspect, but require consistent maintenance to prevent contamination. This attribute favors applications where regular maintenance is feasible and enhanced cooling or lubrication is desired.Q: What advantages does a polished finish provide in these bearings?

A: A polished finish helps reduce operational friction, lowers wear rates, and contributes to smoother, quieter performance. It also offers additional protection against corrosion, ensuring longevity even in demanding application environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Bearings Category

Non Standard Bearing

Price 3349 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Outside Diameter : 200 mm

Structure : Non Standard

Number Of Rows : Single Row

Anti Friction Bearing

Price 1150 INR / Piece

Minimum Order Quantity : 1000 Pieces

Material : Chrome steel

Outside Diameter : 52 mm

Structure : Single row ball bearing

Number Of Rows : Other, 1

Split Roller Bearing

Price 331 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Other, Alloy Steel

Outside Diameter : 200 mm

Structure : Split Roller

Number Of Rows : Single Row

SS Pin Bearing

Price 2347 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Stainless Steel

Outside Diameter : 100 mm

Structure : Solid cylindrical

Number Of Rows : Single Row

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese